| Digital Columnar Cell REM DJS-Z | |

|---|---|

| Rated range | 40t |

| Accuracy class | OIML C6 |

| Creep | 0.0127%F.S |

| Repeatability | ≤±0.0055%F.S |

| Temperature effect on zero | ≤±0.098%F.S/℃ |

| Temperature compensation range | -10℃~+40℃ |

| Operating temperature range | -30℃~+70℃ |

| Stored temperature | -40℃~+80℃ |

| Excitation Voltage | 7~15VDC |

| Lightning surge protection | 100000A(8/20μs、Class I impulse current withstand test |

| Communication Mode | RS485 |

| Safe overload | 200% |

| Ultimate overload | 300% |

| Protection class | IP68 (3m water depth for 7 days) / IP69K |

| Material | Elastomer:Stainless steel/shell:stainless steel/ connector: plug-in aviation plug that meets military standards |

| Group weighing method | Connection operating way |

| MK Digital Bridge Cell QSD | |

|---|---|

| Rated load | 40T |

| Accuracy class | OIML C3 |

| Sensitivity | 2.0±0.002mV/V |

| Comprehensive error | ±0.05%F.S |

| Creep (30 min) | ±0.02%F.S |

| Temperature effect on zero | ±0.02F.S/10℃ |

| Temperature effect on output | ±0.02F.S/10℃ |

| Input resistance | 750±10Ω |

| Output resistance | 703±2Ω,703±5Ω(L≥15m) |

| Insulation resistance | ≥5000MΩ |

| Operating Temp Range | -30~70℃ |

| Safe overload | 150%F.S |

| Ultimate overload | 300%F.S |

| Rated excitation voltage | 10~12V DC |

| Maximum excitation voltage | 15V DC |

| Protection Class | IP68 |

| Material | Stainless Steel |

| Cable Length | 15m |

| MK Columnar Digital cell | |

|---|---|

| Project | Parameter |

| Rated load | 40t |

| Accuracy Class | OIMLR60C3 |

| Creep | 0.015%F.S/30min |

| Temperature effect on output | 0.01%F.S/10℃ |

| Temperature effect on zero | 0.012%F.S/10℃ |

| Temperature compensation range | -10℃~+40℃ |

| Operating temperature range | -30℃~+70℃ |

| Supply voltage | 7~15VDC |

| Communication baud rate | 9600/19200 |

| Communication Mode | RS485 |

| Safe overload | 150% |

| Ultimate overload | 300% |

| Protection Class | IP68/IP69K |

| Material | Alloy Steel+Stainless Steel housing |

| Wiring Method | Incentive+(VIN): Blue Incentive-(GND): Black Signal + (485-A): White signal-(485-B): Red |

| UTILCELL Digital Columnar cell 730D | |

|---|---|

| Model: | 730D 30t/40t |

| Cell structure: | Pressure column type |

| Rated Capacity: | 30/40 tons |

| Maximum safe overload: | 150%FS |

| Accuracy class: | C4 |

| Creep (30 min): | <±0.012% FS |

| Temperature coefficient of zero: | <±0.01% FS /5℃ |

| Range temperature coefficient: | <±0.006% FS /5℃ |

| Non-linear: | £±0.010%F.S |

| Hysteresis: | £±0.016%F.S |

| Repeatability: | <±0.01% FS |

| Operating temperature range: | -30°C~+70°C |

| Weighing indicator REM DI2069 |

|---|

| Product Features: |

| ▲ 1. 7inch 800 * 480 TFT color display makes the display more exciting; |

| ▲ 2. Fast and accurate touch screen operation; |

| ▲ 3. Each function has image-text detailed description and error prompt; |

| ▲ 4. Multi-image digital scale adjustment interface, make the digital advantages of truck scale better; |

| ▲ 5. Various weighing platform status analysis interfaces, making it easier to eliminate installation hazards and investigate problems; |

| ▲ 6. Support Chinese and English touch full keyboard input, coupled with quick input method of license plate number and article number, making weighing information input more convenient; |

| ▲ 7. Support detection information more IoT E-type protocol; |

| ▲ 8. Sensors and external equipment adopt electrical isolation protection design to improve the long-term stability and reliability of the system; |

| ▲ 9. Support to view more detection information of each sensor, such as internal temperature and humidity, load and overload information; |

| ▲ 10. Dedicated management functions for memory car number and weighing record, making it easier to manage big data; |

| ▲ 11. Support IoT function, let customers know the status information of weighing platform anytime, anywhere; |

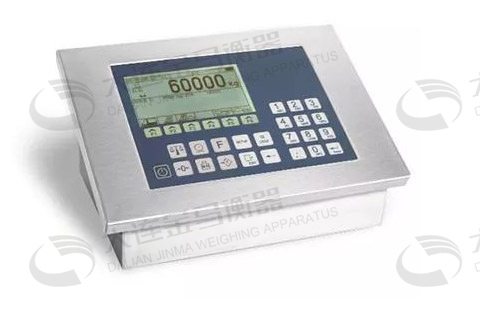

| UTILCELL Weighing indicator MATRIX II 89400D |

|---|

| Technical Parameters: |

| ◆ LCD display, monochrome, 240 × 128 pixels; |

| ◆ OIML R76 and EN 45501 certification can set univariate and multivariate; |

| ◆ Calibration and configuration of the instrument via keyboard or remote communication; |

| ◆ By adding an interface board, the MATRIX II analog meter or MATRIX II digital meter can be connected to two load cell signals; |

| ◆ Time and date; |

| ◆ Multi-function front-panel buttons and PS / 2 interface for standard PC keyboard; |

| ◆ Instrument power: AC 100-240V (50 / 60Hz) or DC 10-24V; |

| ◆ Instrument power: AC 100-240V (50 / 60Hz) or DC 10-24V; |

| ◆ Multi-range function, allowing two ranges, each range corresponds to a different graduation value; |

| ◆ Custom ticket function; |

| ◆ Linear calibration function; |

| ◆ Calibration lock function: The instrument's rear panel is equipped with a mechanical calibration lock, and the internal software of the meter also has a calibration lock setting to prevent the meter parameters from being modified at will; |

| ◆ 32-bit microprocessor, rewritable memory, support software updates for new applications; |

| ◆ Alternative applications: truck scales, industrial weighing and batching; |